The cooling systems of any electronic equipment require a heat sink in order to control the high-temperature levels they generate. Considering extruded heat sink profiles, among other factors, have certain advantages in terms of protecting any device.

Extruded aluminum heat sinks are ideal to achieve heat dissipation and at the same time generating energy savings, so they are generally used in different industries, such as automotive, and industrial electronics, among many others.

Heat sinks in general, need high-performance processing, which involves a highly recommended material, such as aluminum. In the case of extruded aluminum heat sinks, they can be made of high-pressure die-cast aluminum and drawn aluminum alloy welding.

What are the benefits of this type of heat sink?

High corrosion resistance

The extruded aluminum heat sink is characterized by a high level of resistance to corrosion or rust, which makes it have a long service life. Due to its thick film surface and solid oxide, it lasts much longer in high-temperature water.

Energy saving

Aluminum is the most popular material for manufacturing heat sinks due to the low energy levels it requires, which means a significant percentage of consumption savings.

Extruded aluminum heat sinks perform their function of dissipating high temperatures up to 2 times more than cast iron heat sinks.

Low cost

It is proven that the heat dissipation effect is much higher when they are made of copper, however, both the manufacture of the extruded aluminum heat sink and the purchase of the part is much more economical.

Aluminum is very popular in various industries because it is a much cheaper material compared to others and easy to obtain. It is estimated that the price of aluminum is one-third of the cost of copper, so the low cost is a great advantage.

Lightweight

Aluminum as an alloy material is, among other characteristics, very light, making it much easier to install, handle and transport.

Extruded aluminum heat sinks are very popular for this reason, especially when it comes to installations in portable electronic equipment, as being lightweight makes it much more suitable for such devices.

Increased safety

This type of heat sink has a specific resistance, especially when compared to others made of copper, iron, or steel. Since it can withstand high levels of pressure and impact, there is less risk of damage or errors while handling or installing it.

This makes it much safer to use and the risk of accidents during fabrication and handling is very low.

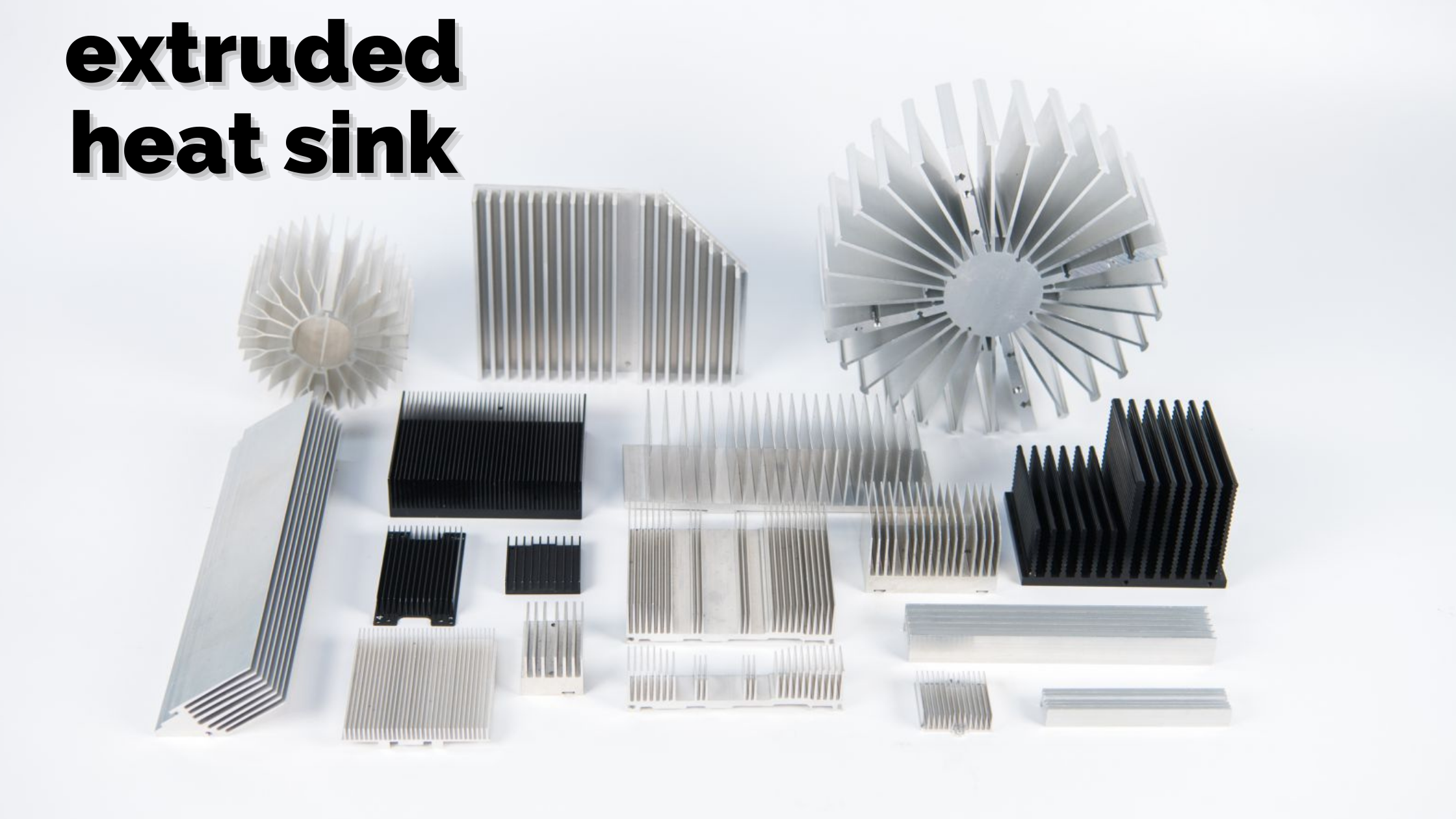

There are different extruded heat sink profiles, which means that this type of heatsink can be manufactured in different welds, with specific fins according to the need of the devices, and even in a variety of colors and sizes.

Those who want to purchase an extruded aluminum heat sink will get in return a product that in addition to having excellent thermal conductivity, has a very low cost for any budget.

It is a very versatile heat sink, which depending on the needs, can be used as a chip for the motherboard of the device or simply as a system to dissipate heat. All these advantages make the extruded aluminum heat sink ideal not only for retail purchase but also for mass production or manufacturing.